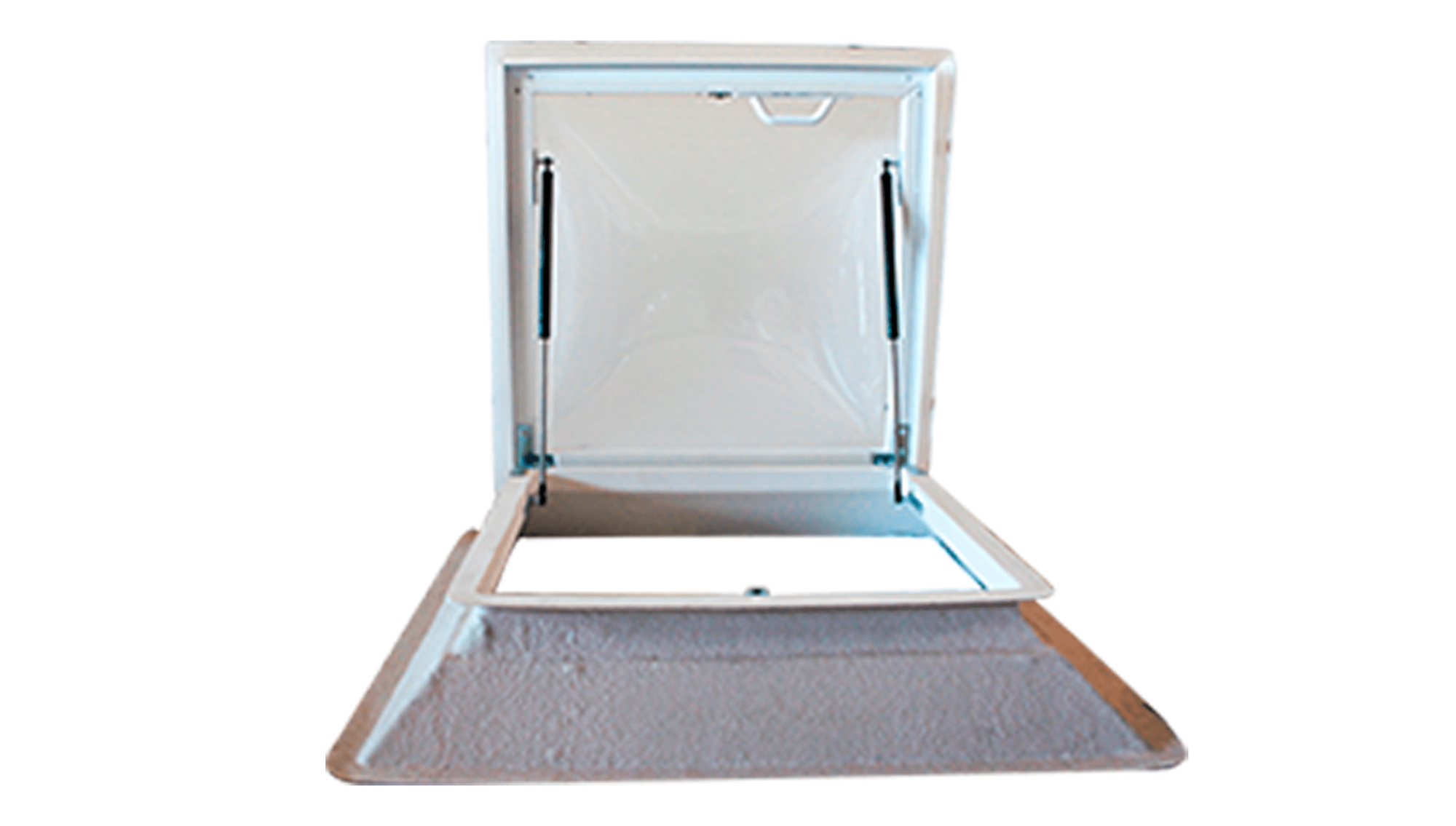

The base of the plinth, and therefore of the skylight as a whole, can have three possible shapes: square, rectangular or circular. In this way, the shape of the dome can also vary depending on the preferences of the client or the shape of its base.

Depending on the specific need of each situation, the type of base to be adapted to the hole in the roof can vary. Below we will show the different possible materials for the manufacture of the base plinth:

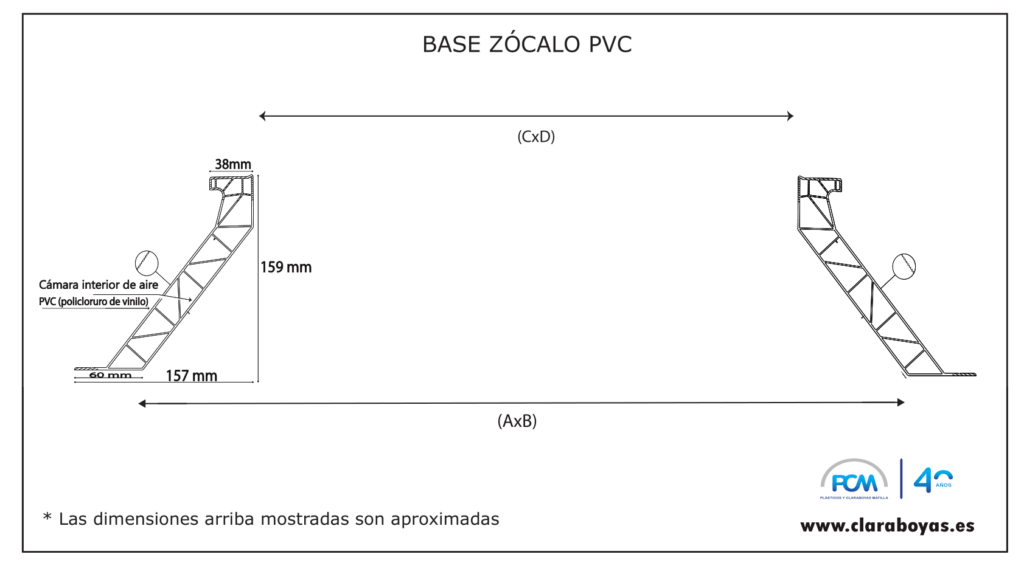

PVC:

The PVC base uses a high-quality polyvinyl chloride, manufactured with a high density resin and ultraviolet protection that gives it a high resistance to inclement weather, with an elegant and robust finish that makes it a great design solution. Like the fiber plinth, it has a side slope of approximately 45º that facilitates the evacuation of rainwater. In addition, its external face has a roughness that facilitates the adhesion of insulating materials on the roof.

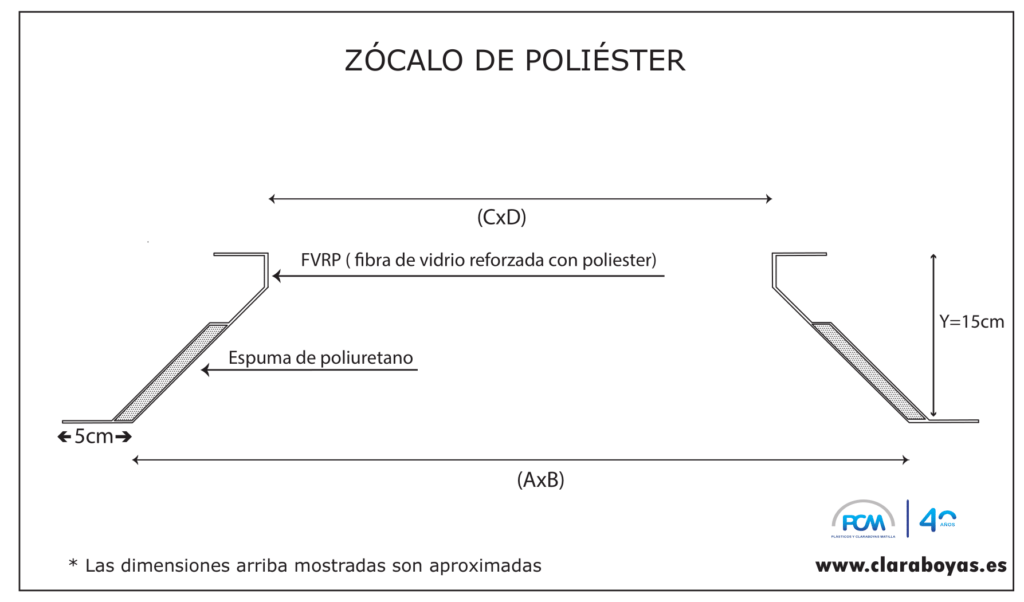

POLIESTER:

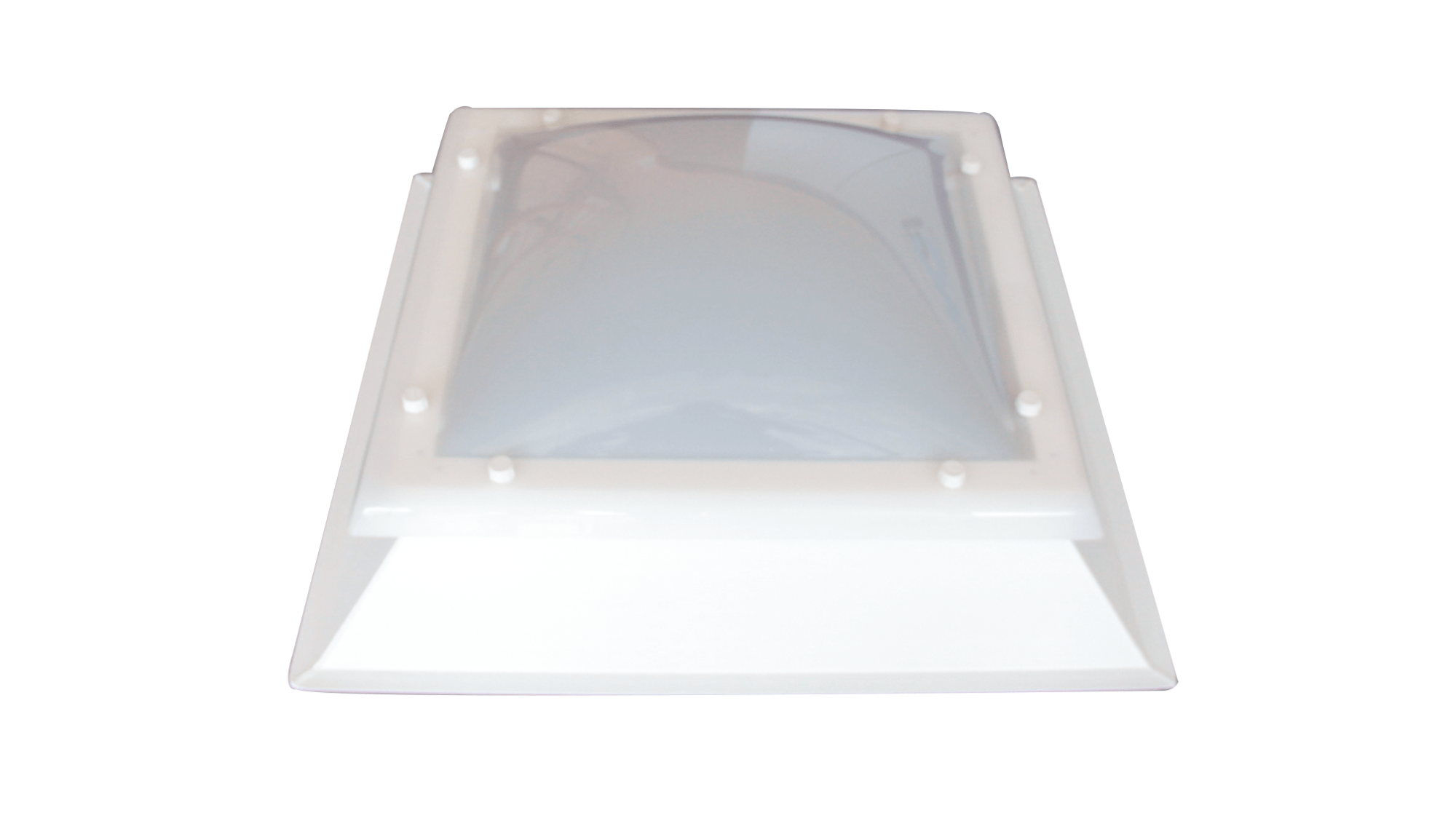

Manufactured with polyester resin reinforced with fiberglass (GRP), with lateral thermal insulation type “sandwich” based on polyurethane foam in order to obtain greater resistance and high insulation index. The profile has been studied in such a way that it has the greatest light opening. Despite the rigidity of its structure, the seat skirt or wing is as soft as possible, so that it adapts easily to the irregularities of the roof, and receives well the various layers of waterproofing. The interior finish of the BASE-Socle is made with white Gel-Coat. The height of this socket is 15cm.

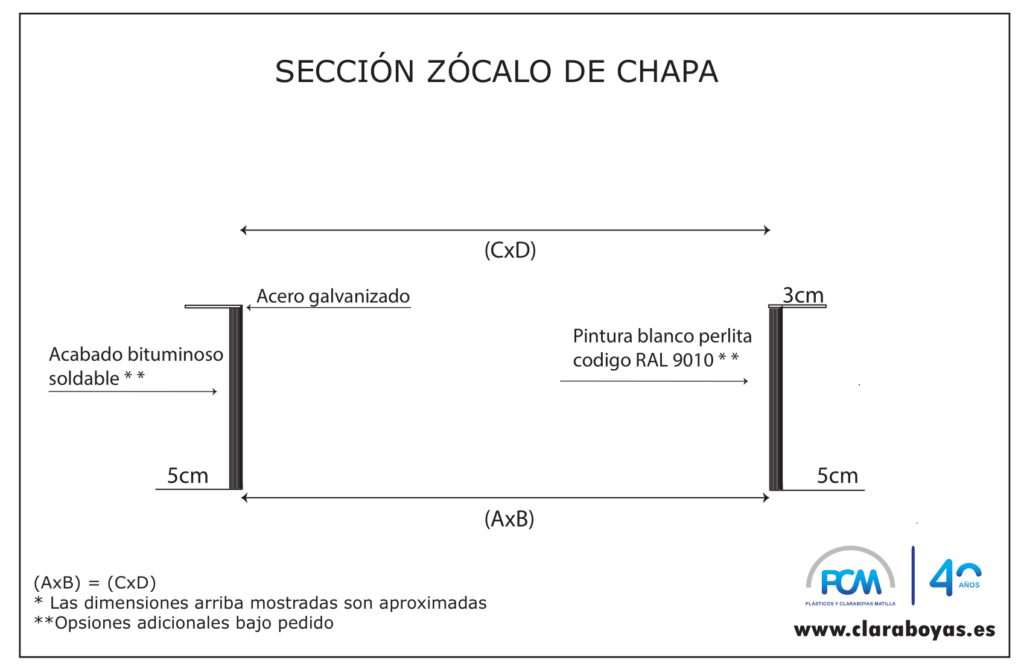

GALVANIZED STEEL:

The galvanized steel base is manufactured on demand, so it can be configured to the exact needs of the consumer, making it possible to choose the length, width, height and even color of the interior. It complies with the UNE10204: 2006 standard, it has a zinc coating Z140 and a thickness of 1.5mm. By default, it is manufactured with straight walls of 30cm. of height, 5cm. of lower support flange and paint with code 9010 of the RAL range (pearl white) on its inside face. Likewise, for the outer face of this plinth is usually used a bituminous insulation with weldable finish, 15mm. thick and protected by a polypropylene membrane.